流程图

语料库¶

基础语料¶

制作:

- make

- produce

- do

- process

- manufacture

设备:

- machine

- equipment

- device

- facility

收集:

- gather

- collect

筛选:

- select

- filter

分类:

- sort

- classify

- categorize

传送:

- transport

- deliver

- transfer

- ship

- carry

- send

- convey

- dispatch【强调“快速、高效发送”】

- distribute

塑性:

- shape

- form

- mould

模具:

- mould

带:

- production line【生产线】

- conveyer belt【传送带】

打包:

- pack

- package

- wrap

- box

- palletize

运输车:

- lorry

- trunk

型号、形式:

- form

- type

半成品:

- semi-manufactured goods

- semi-finished products

成品:

- end product

- finished product

工程类¶

- 熔炉:furnace / kiln

- 冷却室:cooling chamber

- 挖掘机:digger

- 粘土:clay

- 苏打灰:soda ash

- 金属网:metal grid

- 钢丝切割机:wire cutter

- 干燥箱:drying oven

- 大块:big chunks

- 小块:smaller pieces

- 分离:segregate

- 砾石:gravel

- 木炭:charcoal

- 槽:tank

- 压碎器:crusher

- 粉末:powder

- 研磨机:grinder

- 旋转:rotate

- 石灰岩:limestone

- 磨粉机:mill

化学类¶

- 染色:dye

- 漂洗:rinse

- 捣烂:smash

- 分离:separate

- 萃取:extract

- 提炼:refine

- 过滤:filter

- 焚烧:incinerate

- 氧化:oxidize

- 溶化:dissolve

- 褪色:fade

- 溶解:melt

- 发酵:fermentation

- 甄选:screen

- 原木:timber

- 打包:baling

用品类¶

- 液化玻璃:liquid glass

- 使液化:liquefy

- 清洗:wash/purify

- 杂质:impurity

- 融化的:molten

- 废物回收站:collection point

- 高压水:high-pressure water

- 回收厂:recycling plant

- 回收站:recycle bin

- 扔:dump

- 零售商:retailer

- 玻璃容器:glass container

- 拆除:dismantle

能源类¶

- 挖坑:dig a pit

- 厂房:powerhouse【“动力室”或“发电厂”】

- 钢管:penstock

- 水库:reservoir

- 发电机:generator

- 汽轮机:turbine

- 电缆:cable

- 转换:convert

- 变电站:transformer station

- 反应器:reaction

- 压力容器:pressure vessel

- 混凝土盾构管:concrete shield

- 导管:duct

- 热交换器:heat exchanger

- 水蒸气:steam

- 循环:circulate

- 控制器:controller

生物类¶

- 孵出:hatch

- (鱼、蛙)产卵:spawn

- 孕育:breed

- 从……获取营养:feed off

- 以……为食:feed on

- 上下游:upper/lower river

食品类¶

- 成熟的:ripe / mature / full-grown

- 未成熟的:unripe / raw

- 收获果实:reap

- 收割庄稼/产出作物:harvest / yield

- 冷藏库:cool storage

- 去皮:peel

- 密封:seal

- 风味:flavour

- 酱:sauce

- 检查:inspect

设备类¶

- 水龙头:tap

- 水箱:water tank

- 锅炉:boiler

- 导管:pipe

地理类¶

- 蒸发:evaporate

- 密云:dense cloud

- 降雨:precipitation

- 喷发:eruption

- 断崖:cliff

- 侵蚀:erosion

其他类¶

- 填表:fill the form

- 失败:fail / unqualified / fail to meet the requirement

表达集¶

引入:

- The given … detail the producing procedure of …… in various phases, thereby fulfilling the demands of … projects.

- The … shows that the …(life) cycle of … can be broadly divided into X stages.

开始/第一步:

- This system commences with doing sth ……

流程接续:

- following it is ……

- it is followed by

- once ……, ……

- At the X/this stage……

- This stage ends with ……

- ……, before ……

- ……, marking the end of one cycle and the start of the other.

流程外的内容表述:

- 特征总结

- The third stage is the longest, taking two months, during which time ……

- 变化总结

- There are remarkable changes in the appearance of the insect in different stages.

- 图片细节之场地/环境

- ……, which was just below the surface of soil in certain clay-rich areas,……

- 细节之功能

- in order to filter the big chunks of clay into much smaller ones

- 比如滚轮不只有运输功能,还有进一步分拣功能

- 程度总结

- a moderate temperature

- a higher temperature up to

- 进一步猜想

- they get packaged and delivered by trucks to their final destination, be it a building site or storage.

- They get packaged and delivered by trucks to their final destination, whether a building site or storage.

- “无用”细节勿省略

- 比如正逆时针旋转

- 注意把不同流程、部分关联起来

总结:

- In the nutshell, it is evident that the fabrication/lifecycle of …… encompasses a sequence of X distinct and contiguous stages, constituting a process of moderate/great complexity that necessitates a predetermined progression of steps.

题1¶

【未批改,没有写顺势正】

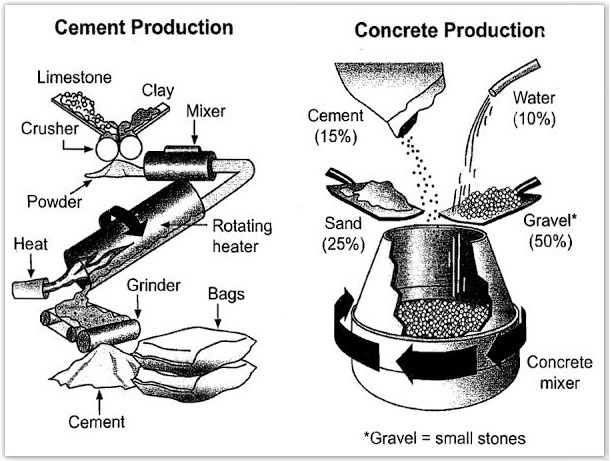

The diagrams below show the stages and equipment used in the cement-making process, and how cement is used to produce concrete for building purposes.

Summarise the information by selecting and reporting the main features, and make comparisons where relevant.

The given diagrams detail the producing procedure of cement and concrete in various phases, thereby fulfilling the demands of construction projects.

This system commences with mixing of limestone and clay through the crusher, which can crush the raw materials into powder. The crushed materials are then transported into a mixer, where they are thoroughly combined. After that, the mixture is then conveyed into a rotating heater, where it undergoes a critical phase of heating to facilitate the fusion of the ingredients. Following it is the grinding, transforming it into the fine powder known as cement. Ultimately, this cement is carefully packed into bags, ready for application in the field of building.

Once the cement is ready, it can be used in the concrete production phase. In this process, cement consists 15% of the mixture, combined with 25% of sand and 50% of gravel——namely small stones. Blended with 10% water, these components are poured into a concrete mixer, serving the purpose of forming a homogenous mixture. The concrete mixer guarantees that all ingredients are thoroughly mixed, resulting in a high-quality and powerful concrete that is essential for construction projects.

In the nutshell, it is evident that the fabrication of cement and concrete encompasses a sequence of seven distinct and contiguous stages, constituting a process of moderate complexity that necessitates a predetermined progression of steps.